De Soto Face Masks Move into High Gear

De Soto Sport’s employees were home. Furloughed. For a lot of companies that furlough will not be temporary.

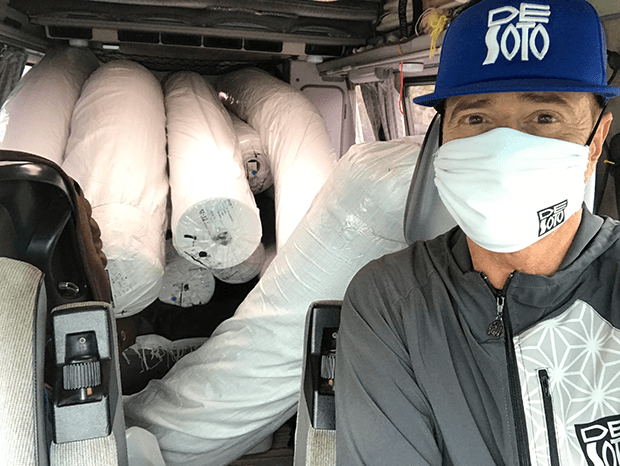

In De Soto’s case, the furlough was very temporary as in, the furlough began Friday and ended Monday. As you and I often find to our embarrassment, a text was sent to the wrong person. Emilio De Soto texted this pic below to his wife Tracy, or meant to, but it came to me by mistake. Emilio had just picked up 2.5 tons of fabric. Tons. For facemasks. I couldn't not write about it.

Facemasks are what brought his factory back to work. De Soto is not a medical services provider; he is America’s favorite (in my view) triathlon apparel maker. Nobody has had time to find out what kind of fabrics and patterns work best for cut & sew masks. He just heard the call, from New York Governor Andrew Cuomo and others: "Get creative… If you can make them, we will give you funding to do it," Cuomo said.

The New York fashion designer Christian Siriano took Governor Cuomo up on the challenge to sew face masks. "I have a full sewing team still on staff working from home that can help,” Siriano said, adding, "I have sewers and pattern makers ready to help working from home we just need all the information on how to help. I am just in a unique scenario where I manufacture everything in New York already, I have a working atelier and everyone's working from home, and my office is a townhouse. We're just able to make them."

De Soto is doing the same, just in his San Diego factory, and without anyone’s funding. He began by giving them to the medical community and, as far as he knew, “free” would be the pathway for as long as the cash held out. “I was selling 1 for every 10 I gave to away. It was expensive. We were paying overtime. We were running out of money.”

The fabric load he picked up, in this photo, is enough for 30,000 face masks and his workers can’t make them all. “I sent a cut for 2,000 masks to a crochet club in Wisconsin. Everybody in this crochet club has a sewing machine at home.”

This design, of a triple layer of Skin Cooler fabric, with a pocket for an optional additional filter, seems to have struck a chord. Now he Emilio sells them, but he has “no idea if we’re profitable. I don’t even know how much these things cost me.”

“I have not worked this hard since 1990,” he told me, which was the year his company was founded. He doesn’t know how long there will be need for his masks. He knows it may not survive April, and his folks may soon again be on furlough. But he holds out hope in the future for a fashion twist to a personal health market, where “One hundred thousand will go to Coachella wearing a mask.”

Start the discussion at forum.slowtwitch.com