Bottom Bracket Standards

I have been accused of circling a subject a couple of times before drilling down to it. I've been told this by the folks who have to listen to me as I take the scenic route on the way to the point.

Yes, sometimes I make a couple of stops along the way, and that's true now. Below is a simple way to understand bottom bracket standards, why this matters to you, and what your proper take-away should be.

The two stops I made along the way were articles published within the past week on Stance Width and Frame Stiffness. The idea here is a trifecta of themes, each of which informs the other.

The irony is that the newest, most relevant bottom bracket standards aren't about bottom brackets. They’re about frame construction, and frame stiffness.

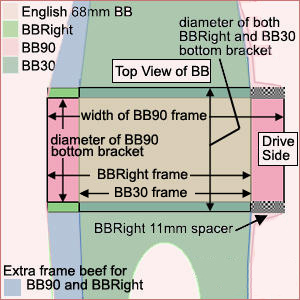

In the old days bottom brackets were 68mm wide. Please pardon what is certainly a confusing diagram above, but that center brownish rectangle represents the size of the bottom bracket shell I used to place in your old QR bikes I made for you. This, if you sat aboard your bike, and looked straight down, and if there was no top or seat tube to obscure your vision.

Bearings were sucked up inside the bottom bracket, and the BB spindle stuck out either end of the BB shell (the shell is the place in the frame inside of which the bottom bracket sits; and the job of the bottom bracket is to give the crankarms a rotating fixture to attach to).

What stuck out of the bottom bracket was a "spindle", the ends of which were square, and tapered. Adjacent is a pic of what an old square taper BB looks like. We threaded this into the BB shell that was the focal point of the bike: cranks attached to it, and the down tube, seat tube and chain stays emanated from it. Keeping this area stiff and strong was paramount then and it is today.

Cranksets back then featured a square hole that fit over a square taper bottom bracket spindle. Greg Lemond won the Tour three times on squarehole cranks, and Mark Allen won the Ironwar on such a crank.

The first significant deviation from the square hole standard was Shimano’s Octalink system, pictured below, that featured a BB spindle with splines in place of a square taper, and these splines fit inside cranks designed to accept them.

This was a patented system, and to get around the patents a group of companies banded together and engineered to a common, open platform spline standard called Isis. All these new splined spindles were larger in diameter than the old square hole spindles, because the old spindles were universally heavy and often made of solid metal. The new splined spindles were hollow, generally lighter, and were stiffer and stronger due to their larger diameters.

But it was tough on the bearings, which had to fit around these larger diameter spindles yet still fit inside of a standard bottom bracket shell that was only 34mm or so in diameter.

BB30

These systems still relied on bearings that sat inside the bottom bracket shell. Cannondale rightly understood the bearing load placed on these larger, hollow spindles required a larger bearing altogether. They increased the 24mm diameter spindles to 30mm, which required an increase in the size of the BB shell as well, to 42mm in diameter. Cannondale introduced the BB30 standard, and this is in common use today by many companies. Note that the 68mm wide shell is still being used by those designing to the BB30 standard. This is important, as well, see in a few minutes.

Meanwhile, Shimano’s view was that the spindle didn’t need an increase in diameter. Rather, Shimano’s Hollowtech II system moved the bearings outboard of the BB shell. This reduced stress on the spindle because of the wider placement of the bearings, and getting the bearings out from inside of the BB shell allowed Shimano to increase the diameter of the bearings. But it added about 11mm to each side of the bottom bracket. This is not necessarily without consequence, as will be explained below.

This brings us almost current. Here's one idea: larger diameter spindle, larger bearings, larger diameter BB shell, but the whole complex is narrower. That’s BB30. Here’s another idea: smaller diameter spindle, smaller diameter BB shell, but the whole complex is wider—it sticks out farther on each side. That's Hollowtech II.

And it's not only Hollowtech. It’s FSA MegaExo, SRAM GXP (an acronym of Truvativ’s Giga-X-Pipe), and every crank and BB that fit into bikes made to accept Shimano components. Adjacent is a nifty, ceramic-bearing, FSA Mega Exo bottom bracket. The threaded section screws into the bike's bottom bracket shell. The bearings stick outboard of the shell, about 11mm on each side.

BB90

Now let’s talk about what Trek did. Its BB standard is called BB90, but it’s really not a bottom bracket at all. It’s the lack of a bottom bracket. Rather than thread cups into a BB shell that accept bearings that sit outboard of the shell (like the Mega Exo pictured adjacent), Trek figured it could just build the frame out and around where those Hollowtech, Mega Exo, GXP, etc., BB cups sit. In a way, it’s a lot like when companies decided to omit external headsets, and just built taller head tubes that incorporated, encapsulated, absorbed the bearings. These sorts of BB standards are called “press fit” because you just press a pair of bearings into the frame, and, voila, it’s a bottom bracket!

Think about what this means for frame strength. The down tube expands out to a bottom bracket shell that’s now 22mm wider than before. It tapers out to the lateral side of the shell on the left side, and the taper is much less on the drive side, in order to make room for chain rings and power meters. Right before the down tube meets the BB shell, the frame makes an abrupt turn and heads out toward the lateral edge of the drive side bearing. The frame can be made incredibly strong in the bottom bracket area using this design motif. Further, and just like integrated headsets, it’s a way just to get rid of bike parts altogether. There really is no more bottom bracket in a Trek BB90 bike. There is a pair of bearings you press into the frame, and that’s it. The two-piece crank consists of the drive side arm with the spindle attached to it that slides through the bearings. Done.

Many bike companies these days are incorporating press fit bottom brackets into their upper end road bikes.

Why did Trek call its standard BB90? Remember, frames were made with bottom bracket shells in the old days that were—and still are in the case of BB30 and Hollowtech II—68mm wide. When Shimano decided to place its bottom bracket bearings outside of the shell (Hollowtech II), the bearings now protruded out an extra 11mm on each side. That’s 22mm in total, added to the 68mm shell, the whole complex is now 90mm wide.

So, BB90 refers to the width of a Trek frame down there in the bottom bracket area, where so much beef is required to make a really strong, stiff frame.

Conversely, BB30 refers to something else entirely: the diameter of the bottom bracket spindle.

BBRight

Then there’s BBRight, and this is Cervelo's standard. This is not pronounced "Be Bright", rather Bee Bee Right, as in, the "right" way to make a BB.

If BB30 and BB90 married and had a baby, it would be BBRight. The idea is as follows.

Cervelo likes the idea of the 30mm spindle that Cannondale pioneered and championed. However, it also likes the idea of the extra frame stiffness that you get when you build the bottom bracket area bigger, fatter, wider, which is what Trek did when it introduced BB90. And Cervelo likes the idea of press fit bearings, which can be found now in bikes built around both the BB90 and BB30 standards. So, it did all of the above.

Almost.

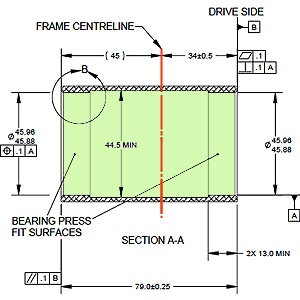

BBRight employs the BB90 idea on the left side of the bike, that is, the non-drive side. On the drive side, it’s like a BB30 bike. Yes, this means Cervelo’s BBRight bikes—like the R3, the S5 and the P5—are asymmetrical at the bottom bracket. The image adjacent is part of a BBRight technical drawing showing the BB from the bottom of the bike. The orange line is the centerline of the bike, the green area represents the dimensions of the bottom bracket shell. The frame is designed to extend laterally 45mm away from the centerline, on the off side, just like a Trek BB90 frame. But on the drive side it's built like a BB30 frame. And, of course, the entire BB is larger in diameter, like a BB30 frame.

Rather than a 68mm bottom bracket—used in BB30—or a 90mm width—as used in Trek’s BB90—Cervelo splits the difference and its bottom brackets are 79mm wide.

Why didn’t Cervelo just go all the way and make its frames a full 90mm wide, like Trek? If you look at a BB90 frame, the extra "beef" on the drive side is very lean beef, because of the stuff you need to make room for on the drive side (chain rings, power meters and the like). So there isn't much if any frame strength to be gained by widening the BB the extra 11mm on the drive side.

However, BB90 does have this advantage over BBRight: It accepts all Shimano Hollowtech II style cranks native (without the use of an adapter). What's the calculation here, on Trek's side? I've heard in the past Trek termed "Shimano's largest worldwide partner" by people who work at Shimano. I don't know if that's still the case, but, it's a broad and wide partnership for certain, and part of Trek's engineering is certainly driven by that close association.

You see what these latter two bottom bracket standards are about, as well as others that have since popped up, like BB386, that uses an 86.5mm wide BB shell and a 30mm spindle diameter. The point is not to omit certain BB parts—though this certainly is a side benefit—nor to make cranks or bottom brackets stronger. They’re already plenty strong and stiff. The idea is to make the frame stronger.

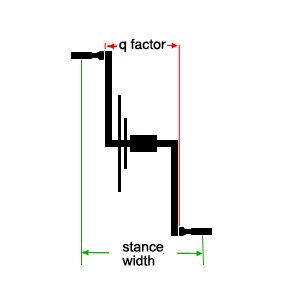

Q Factor, Stance Width and Duck Feet

What does this have to do with stance width?

Remember that road bike stance width is about the same, bike to bike, crank to crank. However, BB30 bikes are built narrower. Remember, a bike designed around the BB30 standard is only 68mm wide at the bottom bracket. So, the crank arms have to—or get to—splay out a bit to arrive at that typical q factor of about 150mm.

Crankarms that attach to a BB90 frame start out wider at the BB, so they taper less as they make their way out to their terminus at the pedal eye.

This means splay-footed folks who need to widen their stance to make room for heel clearance are less in need to do this on BB30 bikes than on BB90 bikes. BB90 and BBRight bikes, as well as any Shimano Hollowtech II or Mega Exo or GXP equipped bikes, have less heel clearance available to them. And when I speak of heel clearance, I’m not talking about heels hitting the chain stays. Rather, I’m talking about heels hitting the crank arm when the foot is directly in front of the crank.

But I don’t want to make too much of this. It’s only a factor for those for whom it’s a problem. And that’s probably not very many people. Still, I’m one of those folks, and I assume I’m not alone.

I've used two cranks that are BBRight compatible, and they are designed to be either BBRight or BB30 cranks. If you add one 11mm spacer to the drive side, it’s a BBRight crank. If you also place an additional 11mm spacer on the other side, it’s now a BB30 crank. This is not the optimized load path for a crankarm. Better if the crankarm make a straight shot out to the pedal, rather than have the spindle extend out for an extra 11mm then make an almost 90 degree turn and head toward the pedal.

But I don’t want to make too much out of that either. The difference in strength and stiffness is extremely minor. However, a BB30 crank that’s BBRight compatible acts like a BBRight or BB90 crank in terms of its taper and clearance. So, if you think a standard 150mm q factor is for you, but you walk, quack and, most importantly, ride like a duck (like I do), then, a BB30 bike with a BB30-optimized crank is, all things equal, a design slightly tilted in your favor.

The most important take-away here is that these new bottom bracket standards, like BBRight and BB90, are designed to make bike frames lighter, stronger, stiffer. Add to that the additional press fit standards, like SRAM's BB30 press fit, and you have some really exciting new achievements in bike construction ideas.