Profile TwentyFour Series

What’s that? You didn’t know that Profile-Design made wheels? Until about a year ago, I had no idea either. Profile came on to the wheel scene rather quietly, introducing a host of products – aluminum training wheels, carbon tubular race wheels, and even some carbon clinchers. The initial products seemed to get a lukewarm reception; nobody was accusing the product of being terrible or outstanding. The wheels were on the heavy side, but the price was right.

I never rode the older wheels, and only spoke to one person that did – Profile-sponsored athlete, Brian Fleischmann. He had a pair of the 80mm Altair carbon tubulars, and remarked to me that they seemed fine, but didn’t feel as light or lively as the wheels he was coming from. Put another way, the wheels were free of mechanical problems, but didn’t exactly make him sing a carbon love song. Brian was only on contract for aerobars at the time (not wheels), and they had sent the Altairs to him for a dose of heavy miles and feedback.

Going Wide

Back in March of this year, Profile-Design reached out to me to send a pair of their new TwentyFour Series wheels. According to them, the wheels were all-new and would effectively reset my expectation of what a Profile wheel should be.

Like almost all new wheels today, the TwentyFour Series wheels are wide. To be precise, they measure 24.4mm from edge-to-edge at the braking surface in both carbon clincher and tubular versions. The carbon clinchers have an internal width of 17mm, a maximum tire pressure rating of 120psi, and are compatible with both latex and butyl inner tubes.

Here is the full price and weight break down, along with a weight comparison to the equivalent older Altair product:

58/TwentyFour carbon clinchers: $1,800, 1630 grams (Altair 52 carbon clincher – 1701g)

58/TwentyFour tubulars: $1,700, 1417 grams (Altair 52 tubular – 1495g)

78/TwentyFour carbon clinchers: $2,000, 1820 grams (Altair 80 carbon clincher – 1895g)

78/TwentyFour tubulars: $1,900, 1580 grams (Altair 80 tubular – 1,658g)

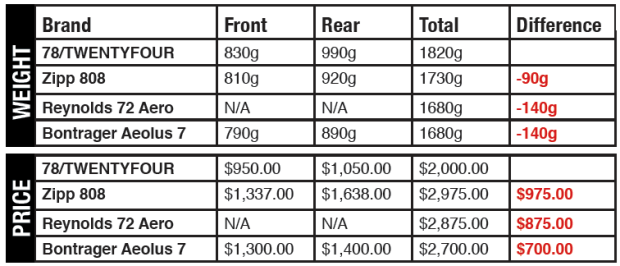

Looking at the prices and weights, you’ll probably notice that the Profile carbon clinchers are, on average, still heavier and less expensive than most of their key competitors. They provided a price/weight break down of several competing wheels for me – this is the deep-section carbon clincher chart:

I wanted to try more than one wheel, and opted for a mixed pair (58mm front, 78mm rear) of carbon clinchers.

One of the first things that struck me about the wheels was that the bead hooks looked rather thick. If you’re not a big wheel geek, you’ll just have to trust me that a 24.4mm external width is quite wide compared to a 17mm internal width. For comparison, my alloy-rimmed Shimano C50 clinchers have the same 17mm internal width, but only a 22.7mm external width.

I think that we’ll see this trend continue. The challenge with any carbon clincher wheel is heat-related safety. If a carbon rim heats up too much during braking, it can literally melt – causing catastrophic failure with a clincher-style rim. All carbon clincher manufacturers advertise that they use special high-heat resin in their rims to combat this.

Another solution (and this is coming from me, not Profile) is to use a thicker rim. There is more material that has to be heated up. I have to think that the rim will hold on to heat longer, too, but I don't know if there are any safety-related implications with that.

Profile delivers the wheels with everything you need – valve tools and extenders, rim tape, quick release skewers, a freehub spacer, plastic tire levers, proprietary brake pads, and even spare spokes.

One thing I noticed is that the supplied freehub spacer is an odd 0.9mm spec. The new 11-speed freehub standard is 1.85mm longer than the previous 9/10-speed model, requiring a 1.85mm spacer to be used in addition to any other spacers when using anything other than an 11-speed cassette. I’ve been around long enough to know that freehub standards tend to include at least some measure of voodoo and black magic – meaning that the on-paper specification doesn’t always flesh out in the real world. I used the Profile spacer along with a Shimano 1mm spacer and 10-speed Ultegra cassette, and it worked fine (on paper, I needed another 0.95mm). Everything was solid, and there was no creaking from a wobbly cassette.

I was once told by a wiser mechanic than I, “If it runs, run it!” I ran it.

Are you going to nod off to sleep if we don't start talking about aerodynamics? It appears that Profile-Design came to this gun fight prepared with facts and figures.

When I first pulled the wheels out of the box, I could tell that Profile had done some homework. I’ve ridden enough wheels, seen enough data, and talked to enough experts to have a reasonable idea of a wheel’s speed by just looking at it. I think most of our tech-savvy readers do, too (that’s you). It’s no secret that many high-end carbon wheels are starting to look and perform alike. They’re getting wide at the braking surfaces and staying wide until they reach the spokes. On many wheels, that inside rim edge (where the spokes terminate) is now as blunt as the tire on the opposite edge of the rim.

I mention that not as a promotion of Profile over any other brand, but rather a public service announcement to our readers: It’s getting harder and harder to find a slow wheel at any price. In my opinion, you’re being freed up to shop based on other attributes such as price, durability, and braking surface material. Even if Profile outright lied to me with their numbers, I’d be shocked if independent tests showed that these wheels were significantly faster or slower than a Hed Jet, Flo, Mavic CXR, or Zipp Firecrest.

My opinions aside, here is what Profile had to say:

“We tested at the FASTER tunnel in Phoenix AZ. We used the same two tires on all tubular wheels tested on a Scott Plasma 10 frame – Vittoria Corsa CX 23mm with pressure set to 120psi. We tested every 2.5 degrees -20 -> 0 -> 20 degrees with two measurements at each angle of attack. We did 5 tests for the TwentyFour wheels to have a sample size of 10, and 2 tests for the Armada and Zipp wheels to have a sample size of 4 at each angle of attack (AOA).

The Zipp wheels were current model year Firecrest 404 and 808s. The better performance [of the Profile wheels] on the course modeling is due to the low wind speeds reducing the AOA. A mistake many people make is that a reported 15mph wind speed from a weather station is recorded from about 10 meters off of the ground. The ground wind speed is typically about 50% of reported wind speed.”

Here are the actual numbers that Profile quoted to me:

58/TwentyFour

-Comparison Using Environmental Data from 2012 Kona Ironman World Championship and our wind tunnel testing data

-6 minute savings compared to the Profle Design Armada 24

-A 5 hour bike finisher nets a 3 second time savings compared to the Zipp 404

78/TwentyFour

-Comparison Using Environmental Data from 2012 Kona Ironman World Championship and our wind

tunnel testing data

-7 minutes and 15 seconds savings compared to the Profile Design Armada 24

-61 seconds savings compared to the Zipp 808

Take it or leave it – that’s what they said.

Test Ride Impressions

I’m not one to look at a sheet of numbers and assume a wheel is good or bad; it needs to be ridden. Because I’m also a tire geek, I wanted to try something new. Our friends at Challenge were kind enough to send a pair of 700x23mm Forte clinchers, which we wrote about in Part 2 of our Fast Tires series this year (linked at the bottom of this page).

I also used Profile’s proprietary red brake pads, pictured here:

With everything installed, the wheels were ready to roll:

My first ride was on a warm 70 degree, sunny day in Colorado. I ran the tires at 100psi, and did a mixed course that involved flats, climbs, and descents. The wheels seemed to do everything they should. Based on first impressions, I couldn’t tell a difference between these wheels and something that cost $1,000 more. I don’t nit-pick ride quality, because I can’t tell a difference between most average wheels that aren’t outrageously stiff or wimpy. Sorry, but that’s the honest truth.

What really impressed me was the braking. With the Profile pads in Dura Ace 7900 calipers, it was smooth, strong, and predictable.

One of my later rides was quite different:

The ride started at a reported 47-48 degrees Fahrenheit with overcast skies. After I began riding, it quickly dropped about ten degrees and started pouring rain. In these conditions, the braking performance changed dramatically. To make a long story short, the stopping power decreased, and stopping distances increased significantly. While going down a descent that is a 3-4% grade and normally takes about five minutes, I had to lay hard on the brakes almost constantly to keep my speed in control – after all, I always want to be able to stop in case of an animal or automobile on the road.

On a positive note, the Challenge tires gripped nicely and didn’t puncture, despite there being debris all over the road.

I reported my experience to Profile, and here’s what they had to say in response:

“Knowing that bikes stop because brakes convert the forward motion of the bike into heat, we designed our rims and pads with materials that are designed to perform at higher temperatures. This results in shorter stopping distances/times and more consistent brake modulation under normal conditions when compared to our Altair wheels. The pads are the easiest way to detect the differences. Just compare the hardness of our pads to other pads on the market. We tested a few different brake compounds in the lab and in the field – some softer, some harder. Softer compounds produced shorter stopping distances, but modulation and consistency were poor. Harder compounds produced good modulation but longer stopping distances. We also looked at different friction materials in the rubber and actual rubber compounds but we’ll keep it at soft vs hard for simplicity. We also tested a well-known [company’s product] that makes a softer compound resulting in extreme pad wear due to high temperatures; basically completely worn after one ride.

With that said I think the [near] freezing temperatures combined with the rain didn’t allow for the heat build-up that makes our stiffer pads perform so well under normal circumstances. If the weather warms up out there and you are brave enough to endure some rain I believe you will find the braking much better. A softer compound that would normally overheat and perform poorly or fail under normal conditions with our rims might be ideal in temperatures below 32f and raining.”

Indeed, just holding the Profile pads in your hand, you can feel exactly what they mention. The pads are quite hard. Unfortunately, I did not have any other pads with me at the time of my rainy ride, and I never had the chance to ride the wheels in identical conditions (the following months in Colorado featured drought conditions and severe wildfires).

Was it the thick heat resistant rims? Was it only the pads? I’d like to try the wheels with Swiss Stop yellow pads or Zipp’s Tangente Platinum pad, as those both feel softer and have worked well for me in the past. I’m also curious whether the Profile pads behave similarly on a different brand of carbon wheel in cold weather – although I’m admittedly nervous to try it after my descending experience.

What I’m really wondering is if we’ll eventually see brake pads for carbon rims that are made for a specific temperature range, or if this is just a one-off fluke. I personally have very few miles on any brand of carbon wheel in weather that is both cold and wet. It may seem like this is a superfluous conversation, as most of us use our carbon wheels in race season – but I think that is changing quickly. Manufacturers want to sell carbon wheels to us to use for training, racing, and going to the coffee shop. They are now for all rides and all conditions. As well, there are certainly plenty of triathlons that happen in cold weather – do Rev3 Knoxville and Norseman Xtreme ring a bell? What about odd years at Ironman Wisconsin or Lake Placid?

I don’t know where this is going to end up for the market at large. In the short term, I feel that Profile needs to make a second pad compound for colder conditions, or at least offer a specific recommendation for a different brand of pad. The TwentyFour Series wheels execute the other key performance areas (aerodynamics, stiffness, build quality, dry braking) very well, and are a fine choice for those that live and ride in warm climates. However, I cannot recommend them for use in wet/cold weather until we have an improved pad solution.

Start the discussion at forum.slowtwitch.com