ENVE Launches SES Road Tires

ENVE is officially in the tire business. This shouldn’t come as a complete surprise, as the wheel-tire ‘system’ approach has been touted for years by competitors such as Specialized, Mavic, Zipp, Trek/Bontrager, and Giant/CADEX. We’ve known about these tires for quite some time, and got an in-person preview during our visit to the ENVE factory in 2019.

What’s the design philosophy of the tires? Most aero? Lowest rolling resistance? Something else?

ENVE stuck to their “real world fast” design philosophy, which translates to the desire for a balanced approach. They wanted the tires to be among the top competitors in all categories – without the need to “own” one single category.

Well, there is one category in particular in which they wanted to excel – and it’s one that doesn’t get a lot of air time. We already touched on this topic after our tour of the ENVE factory – the issue of tire bead manufacturing. In order to achieve a safe and reliable tubeless tire fit – especially with hookless rim designs – tire bead diameter needs to be made consistently. Large variations in tire diameter result in some tires fitting too tight – and others to loose (the latter being a significant safety hazard). In addition, the tire bead stiffness needs to be sufficient so it doesn’t grow too much in size as pressure increases.

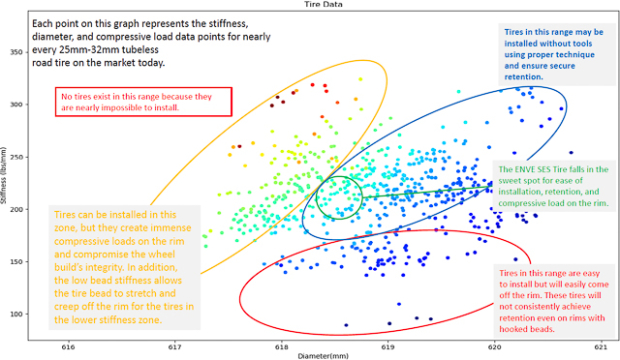

The chart above shows data points from ENVE’s own test rig, which we saw in the flesh. The Y axis represents bead stiffness, while the X axis represents bead diameter. The goal is to have a narrow clump of data points towards the center of the graph. ENVE has a list of approved (and unapproved) tires for their wheels. They generated this list by testing all of these tires – and those that are too far out of the desired range of bead stiffness and diameter don’t make the cut (or if the bead diameter between samples of the same tire model are wildly inconsistent).

In short, the purpose of the ENVE SES tire line is this: To have a legitimately fast and well-rounded performance tire that sits among the best in the world – while also being the top performer in terms of bead stiffness and diameter.

ENVE will make four sizes for the SES tire – 25mm, 27mm, 29mm, and 31mm. If it’s not obvious, these will suite a variety of riding disciplines and conditions. Narrower tires improve aerodynamic performance, while wider tires improve comfort and grip on rough or loose surfaces.

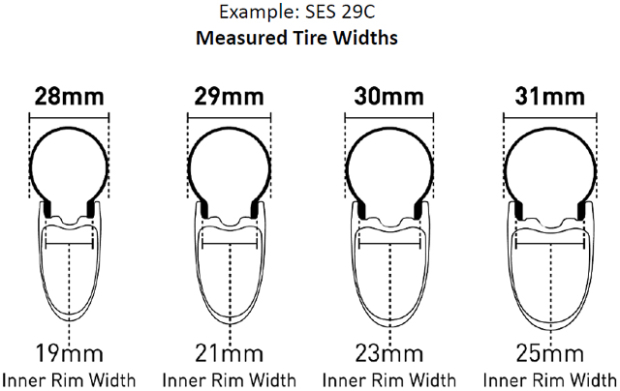

Also note that the inner width of your rim affects the actual inflated tire size. The image above shows inflated sizes for the 29mm SES tire on a variety of rims. In terms of fitting a tire into your bike frame, it’s the actual inflated size that counts, not the size printed on the tire label.

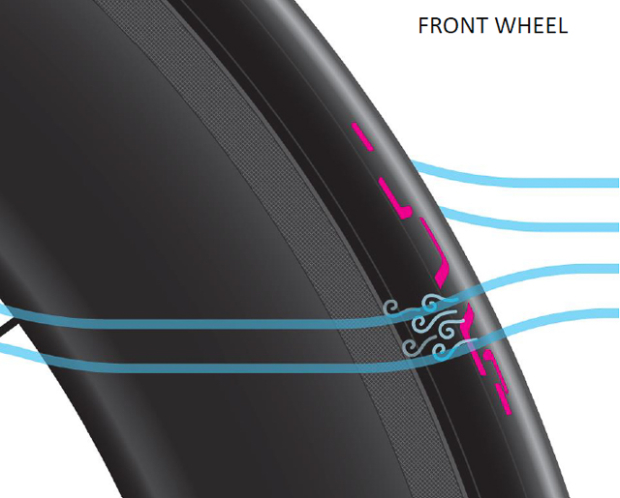

ENVE put thought into their tread pattern, claiming legitimate aerodynamic performance. In addition, the shape of the casing was designed to be not-too-flat, not-too-elliptical, for performance in a wide range of yaw angles.

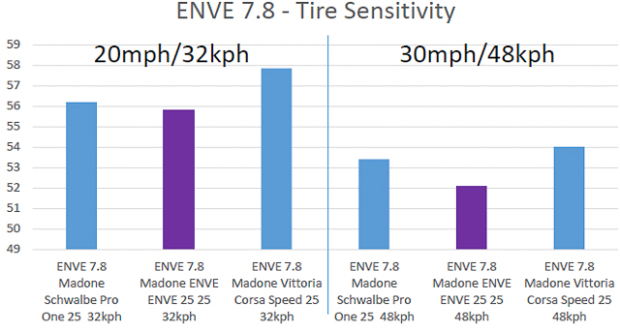

This chart shows the performance of the SES tire compared to the Schwalbe Pro One and the Vittoria Corsa Speed. The Y axis represents watts-to-spin two wheels, without a rider. ENVE claims best-in-class aero performance, and that adding their tires to non-ENVE wheels will reduce aerodynamic drag.

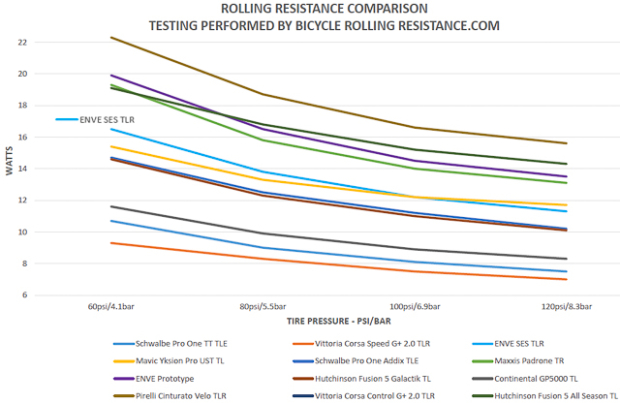

Slowtwitchers are all about rolling resistance, and ENVE provided the above chart to satisfy your desires. The SES tires rank in the middle of the pack, among a group of top performers in the marketplace. The Vittoria Corsa Speed is the fastest roller (on this and several other tests), but it’s also no secret that this tire has a reputation for being very fragile and puncture-prone. I personally tend to pick tires conservatively, and prefer to spend my time riding, rather than fixing flats.

I did get a chance to ride the SES tires several times, during my test of the new Foundation Series wheels, and my seat-of-the-pants power meter told me that they rolled very fast. One tire did have trouble holding air, but these were early preproduction samples.

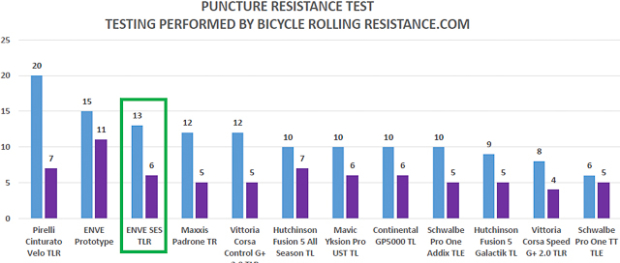

Bicycle Rolling Resistance performed an independent puncture test for the SES tire, seen above (the light blue lines represent tread performance, while the purple lines represent sidewall performance). This brings good news, putting the SES above known performers such as the Continental GP5000 TL. While not seen on this chart, weight is also competitive, at 256 grams in 25mm size – compared to 295 grams for the Conti.

You may be wondering – who makes these tires? Did ENVE open their own factory?

The answer is that ENVE opted to partner with an existing tire manufacturer. They shopped far and wide, and found a single manufacturer that could meet their needs for customization of compound, tread, and construction – AND their stringent requirements of bead stiffness and diameter.

Who is the mystery manufacturer? None other than Tufo. Based in the Czech Republic, they’ve become an R&D partner to ENVE. This came as somewhat of a surprise to the Slowtwitch staff, as readers of our forum are well aware of Tufo’s reputation for poor rolling resistance in their tires from 10 – 20 years ago. Perhaps this is the beginning of a new chapter for Tufo. They were able to hit the manufacturing consistency, quality, and quantity that ENVE needed – while ENVE helped them develop their next generation of tubeless technology. The Crr data shown previously appears to dispel the old reputation for slow-rolling, and we’re optimistic about what the future holds for Tufo.

The SES tire beads are made of a material called Zylon, which is a synthetic polymer. It was chosen for its strength, thermal stability, and ability to resist stretching over time. The tire casing includes Vectran for puncture protection – something seen in other tire brands. Finally, the compound is SPC Silica, said to provide excellent wet weather performance, and good rolling properties.

The 25mm and 29mm sizes of the ENVE SES Road Tires are available immediately. 27mm and 31mm sizes are expected to become available in the coming months. All sizes sell for $75 USD.

Start the discussion at forum.slowtwitch.com