Hooked and Hookless Rim Tech

Today we continue our coverage of road tubeless tires, supplemented by a Super Thread in our reader forum. We’re covering topics in (relatively) bite size chunks, to give you the information to decide whether road tubeless should be in your future, and, if so, how to properly implement it with your bikes.

The topic at hand today is hookless rim shapes. We should make it clear that this style of rim isn’t necessarily something that can only be executed with tubeless-style tires, it’s just something that has largely been executed in tubeless fashion. Until recently, hookless rims were only seen en masse for mountain bikes, but now they’re migrating into road.

Above image © Light Bicycle

What is a hookless rim? Traditional clincher rims have bead hooks that help to secure the tire in place. As you inflate the tire and its beads get pushed outward to the sides of the rim, there is tremendous force being applied to the tire and rim. Although tire beads are tough, they are still a bit flexible, and not every tire has a perfect diameter. Bead hooks act as a retention device to be sure that the tire doesn’t come off, especially when compounded by hard cornering.

Before we go further, we must make an important safety note: Most wheel manufacturers prohibit using standard non-tubeless clincher road tires on hookless rims. Some wheel manufacturers recommend or outlaw the use of some specific tubeless tires too, so always check with the wheel manufacturer before buying tires.

Why the safety concerns? Hookless rims lack the extra barrier to keep a tire from blowing off the rim – meaning that you need the tire beads to be very strong, not very flexible, and manufactured to tight tolerance control. Those are all attributes of tubeless tires, which have thicker, stronger, more precisely manufactured beads. It’s not impossible to make a standard tubed clincher tire with such beads – it’s just that nobody does it or wants to add extra weight if they don’t have to.

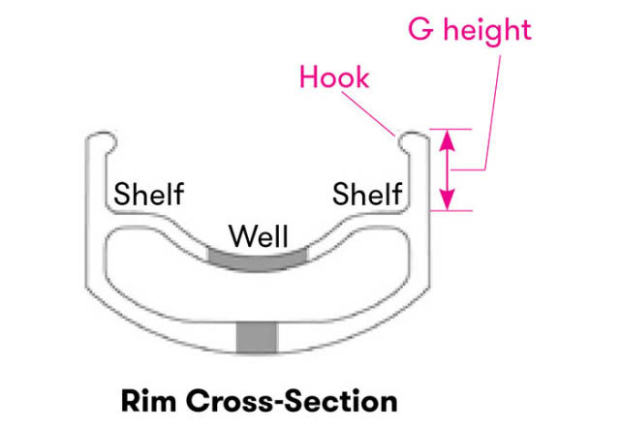

Above image © HED

It should also be noted that it’s not unheard of to use standard tires and tubes with hookless rims for mountain bike or fat bike applications. These situations aren’t quite as touchy or potentially dangerous simply due to the fact that average tire pressures are MUCH lower than road cycling. For example, HED’s Big Deal fat bike wheels can be used with non-tubeless tires, but with pressures below 10psi, the possibility of a blow-off is essentially zero.

Given all of the safety concerns, why bother making a rim hookless? We borrowed this quote from the blog of Rene Herse Cycles (formerly Compass Cycles – a manufacturer of high-end tires): “The hook has a crucial function in keeping the tire on the rim. Other rim and tire makers have tested and found the same: The hook significantly increases the pressure at which the tire safely stays on the rim… Why [make hookless rims]? Mostly because the hook is difficult to make with carbon fiber: It requires a complex 3-piece mold for the rim bed.”

Above image © Rene Herse

They continue, “A ‘hookless’ rim with a shorter G height is stronger and less expensive to make. Stiff mountain bike tires are inflated to ultra-low pressures. They won’t blow off their rims even if there isn’t much sidewall to hold them on. So the non-standard rims have worked fine for mountain bikes. These mountain bike rims usually come with low maximum pressure ratings.”

Money talks, so it shouldn’t be a huge surprise that there’s an economic component for molding expensive carbon rims. However, a hookless rim will also be stronger (all else equal) due to the lack of an extra unsupported edge in the rim, and making the vertical rim wall shorter. Both of these factors also provide weight savings. ENVE echoes this sentiment in their marketing, and takes it a step further by making their outer rim edges super wide to help distribute force over a wide area to reduce pinch flats.

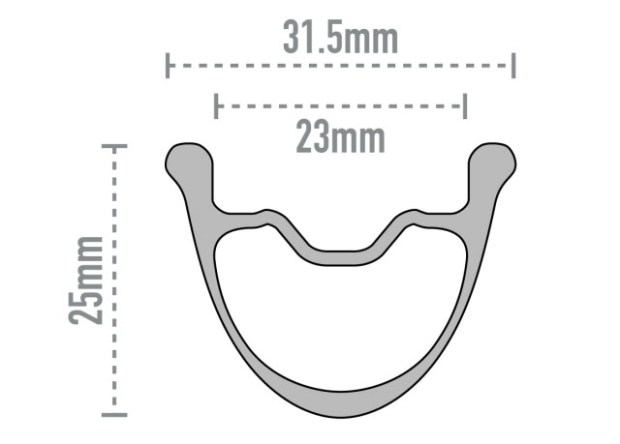

Above image © ENVE

The ENVE G23 gravel rim above shows just how wide and thick those rim edges are, and you can clearly see the lack of inner bead hooks. ENVE claims a 60% reduction in pinch flats with this rim design over competitors’ hookless rims, a significant gain if true.

The cost of hookless is that ENVE’s latest all-road SES 3.4 AR Disc and SES 4.5 AR Disc wheels – both featuring hookless beads – are listed as NOT compatible with the following tires:

-ANY Tube-Type/Non-Tubeless Tires

-Continental GP 5000 TL

-Specialized S-Works Turbo 2Bliss

-Specialized Roubaix Pro 2Bliss

-Pirelli Cinturato Velo

For a full list of compatible tires, check out the ENVE website.

Note, however, that not all hookless road rim manufacturers have these restrictions, with rims like Alto’s CCX40 allowing full use of any tubed or tubeless tire. Alto does, however, have a limit of 100psi for that rim, which may suggest a safety concern for tire blow-off at higher pressures.

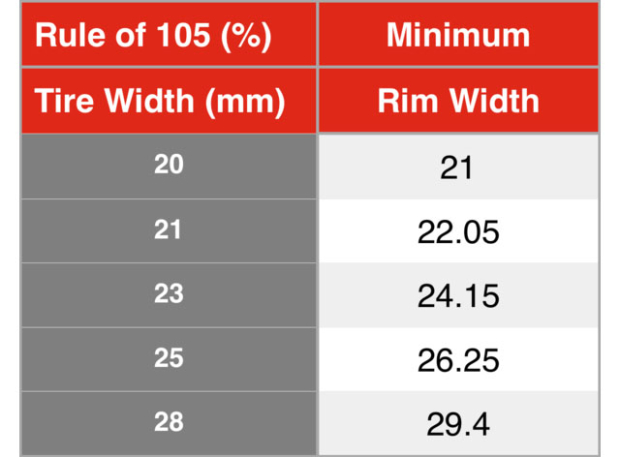

HED has a different take, using hookless rim profiles for their off-road wheels, but keeping hooked rims for road – including their Vanquish carbon clincher line. According to HED’s Dino Edin, the reason is for aerodynamic purposes, not strength. Leaving the hooks on the rim means that the tire width gets pushed in a bit to keep it from becoming too wide. This lines up with the Rule of 105 from Silca’s Josh Poertner, which essentially says that your rim must be a bit wider than your tire for optimum aerodynamic performance. For clincher wheels, this means that you want an inner rim width that’s not too wide, combined with a relatively wide outer dimension (i.e. HED’s internal 21mm width and external 30mm width). Profile Design started this practice years back, with wheels like the Twenty Four series that we reviewed in 2013.

Above image © Silca

And perhaps that’s the divide we’ll see: Aerodynamic-focused wheels keeping hooks, and gravel or MTB-focused wheels going hookless for extra impact resistance. The former situation usually warrants higher pressure with less chance for impact damage or pinch flats, along with faster speeds and more importance placed on aerodynamic gains. Gravel and MTB require a bigger focus on traction – making low pressure very important (and increasing the chance of pinch flats or impact damage in the process) – giving the nod to hookless design benefits.

If you’d like to join in on the discussion, head over to our forum to weigh in with your thoughts.

Start the discussion at forum.slowtwitch.com