This is the second article in a two-part series. For part one, click HERE.

We already covered the basics on the history and application of carbon fiber to bicycles. We know that it can be molded into many different shapes and that it tends to be lightweight. We know that if you want to keep up with the Joneses, every conceivable piece of your bike ought to be made from carbon, right?

This is exactly what Part 2 of this article series will cover – the application of carbon to the subcomponents that make up a bicycle.

Have the Predictions Panned Out?

After setting the stage, it’s time to take look at the different bicycle components to see how carbon fiber has fared in the last 30 years or so. For the sake of simplicity, we’ll make an assumption that – if everything advanced according to plan in the 1980s – virtually every part of our bikes would be made of carbon today (excluding obvious items such as bolts, cables, or chains). What parts of your bike can and should be made from carbon? What parts are best left to steel, aluminum, or other materials? Finally, what about parts that can be made from carbon, but doing so offers no performance benefit?

We’ll divide our results into three areas: Where carbon has stuck around for good, where it hasn’t, and the places that it can go either way.

Where Carbon Has Won The War

1. Frames. While metal frames still exist (and will continue to do so), carbon frames have absolutely earned a permanent spot in the fray – especially at the top of the racing/performance heap. There’s just no denying it. With shape flexibility, tunable ride quality, and obvious aesthetic flexibility, carbon can do many things well. We’ve gotten through most of the growing pains and QC issues, and carbon is now among the most reliable materials.

Above image © Felt

The only asterisk I’ll inject here is that there’s an old wives’ tale that’s still sticking around – that “carbon rides better than ______” (fill in the blank, typically with aluminum or titanium). Carbon bikes can ride nicely. However, like other materials, the ride quality is also highly dependent on the tube shape and thickness. Specific to carbon, you also have the layup schedule and modulus (in short – higher modulus carbon is stiffer but more brittle). The take-home is that you should not assume that a carbon bike is going to have a smoother ride quality than a metal bike. It’s a complex problem that doesn’t have a simple answer. The only wives’ tale that seems to hold relatively true is that carbon has a tendency to feel “dead” compared to a properly tuned steel or titanium bike – which tend to provide a more lively ride quality. Your mileage may vary.

2. Forks. This is perhaps the single area that carbon fiber has had the most lasting success. Carbon forks are everywhere. They’ve been proven to be as safe as any other material, and typically offer a substantial weight savings. Even at low price points, carbon forks are surprisingly common. The only downside is that you can find some low price forks with very questionable stiffness – sometimes leading to braking or handling issues (such forks have plagued me on more than one occasion). As such, I advise adopting a general rule against shopping for the lowest weights or prices.

Above image © ENVE

Where Carbon Has Lost The War

1. Stems. Are there some carbon stems out there? Sure. In fact, more today than ever before. However, they’re far from becoming a mainstream product – and I don’t see that happening soon. The problem is that in order to make one that’s safe and functional, you typically end up with something heavier than aluminum and significantly more expensive. So we end up with some carbon-wrapped alloy stems, and a handful of beautiful high-end/high-price halo products. They have a place and will stay there – it’s just a small one in the grand scheme of the marketplace.

Additionally, carbon stems suffer a problem that is usually seen as an advantage: they’re stiff. This can be great from the perspective of power delivery, but it’s bad for clamping onto handlebars. If you have a carbon stem and carbon face plate – all clamping on to a carbon handlebar, none of those parts want to “give”. When these parts are made of aluminum, they all bend and conform to each other just a little bit when you tighten down the bolts – which actually helps keep everything in place (Note: I’ve worked for a large producer of stems, during which time we had to work through this specific issue). At least one part of the stem/faceplate/bar system needs to be made of aluminum, to ensure safe clamping. For this reason, you’ll see carbon stems with aluminum faceplates, carbon faceplates with aluminum stems, or even aluminum liners hidden inside the clamping surfaces of carbon parts. Consider this your free behind-the-curtain secret for the day.

2. Chainrings. As mentioned previously, carbon chainrings just do not hold up well compared to aluminum or steel. Sometimes you see a carbon covering on an aluminum chainring, or a carbon chainring with an aluminum cap (see image below). Full-carbon rings remain a race-day-only solution for people far richer than most of us.

3. Brake Calipers. There are a few carbon brakes out there, but similar to stems, people seem to value an extra layer of safety for this critical component. Also, we get back to the problem of a properly-functioning finished part being vastly more expensive than an aluminum brake. Unless something big changes, carbon brake calipers will remain a small niche product.

The In-Betweeners

1. Seatposts. Someone will argue with me on this one, but carbon seatposts still haven’t displaced aluminum. As mentioned in Part 1 of this article, there are some fantastic, lightweight, high quality alloy posts, such as the Thomson Masterpiece. If you’re old enough to remember when carbon seatposts were new, you’ll remember some of the growing pains – namely cracked seatposts and aluminum clamps becoming disbonded from their carbon shaft. Many of these issues have been reduced or resolved, but many people still prefer aluminum.

The big exception, of course, is with anything that’s being sold as aerodynamic. Aero carbon posts are typically made specific to each bike, so you don’t have a say in the matter, either. The shape flexibility of carbon wins the aero battle, whether that’s an airfoil, truncated airfoil, or something else entirely. The good news is that most new triathlon frames have better clamping mechanisms than the pinch bolt systems that round posts rely on, reducing the potential for damage to your seatpost.

Above image © TriRig

2. Handlebars. This one is similar to the seatpost argument above. At higher price points and the aerodynamic end of the spectrum, carbon fiber owns the market. For everyone else, aluminum rules the roost.

This is also one area where safety concerns (whether real or imagined) are a persistent talking point. Even if test data shows that a carbon bar will go twice as many cycles as an aluminum bar, many riders will still choose the alloy bar for its perceived safety factor.

3. Cranks. I must admit – I’ve been surprised by the staying power of aluminum cranks. Carbon fiber cranks became popular in the early 2000s, with brands such as FSA, Zipp, and Campaganolo leading the charge. Early indicators pointed towards an inevitable weight reduction with carbon – and perhaps a bump in stiffness and power transfer. Shimano – known for their incredible prowess in forging aluminum – even showed brief flashes suggesting an interest in carbon cranks (below is a prototype of their 7800 series Dura Ace, which never made it to market):

Yet a decade later, there’s been no perceptible shift in market demand for carbon, nor a big push from manufacturers’ advertisements. What happened? Things stumbled. Quality issues came and went. From a practical standpoint, you also have the constant changes in axle diameter, axle material, and bottom bracket “standards” – leading to confusion and costly SKU multiplication for manufacturers. Aluminum soundly wins at low price points, and even occupies several high-end spots.

4. Rims. Similar to many of these other components, carbon fiber starts to show up at the mid-to-high price points. A lasting area of controversy, it appears that the industry is slowly settling on a new paradigm of carbon rims being used for disc brake applications, and aluminum rims for rim brake applications. Yes, there are exceptions – most notably at the ends of the price spectrum.

While it’s generally well known at this point, the issue with using carbon as a braking surface is that it doesn’t shed heat very well (which accumulates during braking). If you heat carbon fiber up enough, it weakens significantly. Moving the braking surface to a separate rotor on the hub (i.e. a disc brake system) removes this particular variable of rim safety – though it is still possible to overheat a disc brake system.

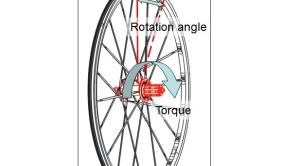

5. Other wheel components (spokes, hubs, axles, etc). This segment almost got kicked into the category of “Carbon Lost The War,” if it weren’t for a few lasting products that have proven themselves. Lightweight brand wheels have a good reputation for quality and safety, even with their near full-carbon construction. Hed has brought carbon hubs back from the dead, with their full fat bike lineup available in carbon. Corima has carbon spokes, as do full composite 3, 4, and 5-spoke wheels from Hed, FSA, Mavic, and others.

Let me be clear: metal components will continue to dominate the subcomponents of wheels for the vast majority of the marketplace. There are just a few persistent high-performers who have managed to make carbon fiber a legitimate choice, if it fits your budget.

6. Saddles (rails and saddle bases). Carbon fiber is a fine choice for making a saddle. There are quite a few out there, and they’re hitting lower prices by the day.

However, they’ve struggled to gain acceptance in the mass market, but not because of anything wrong with the material itself. It’s the practical application and consumer confusion. In order to remain safe, carbon saddle rails require a different shape than the traditional 7mm round tails you see made from steel, titanium, and other alloys.

The problem is that manufacturers of saddles and seatposts can’t agree on the proper rail dimensions – 7x9mm, 7x10mm, 7x9.6mm, or even 8x8.5mm. If your saddle needs a 7x9.6mm-compatible seatpost, but one isn’t made with the amount of setback you need to achieve your best position, you’re out of luck. Retailers can’t afford to stock everything, further hampering the situation.

In addition, many of us use our saddles not only as a place to sit, but also a mounting position for accessories such as rear hydration systems, flat repair kits, lights, and camera mounts (many of which aren’t made to accommodate carbon fiber rails). If you want to play in the saddle game today, you must take this into consideration – or lose market share. More and more saddle manufacturers are accepting this, with some offering their own mounting accessories.

Wrap Up

There’s no doubt that the introduction of carbon fiber to bicycles has significantly changed the trajectory of the industry, the products we use, and our priorities as cyclists. However, I hope it’s clear that carbon has not (and will not) replace the need for steel, aluminum, and other alloys. While price is often a big deciding factor, function is a key component as well – with many parts being better suited to metal construction.

I’ll leave the final conclusion to you, your needs, and your budget. Has carbon fiber revolutionized your world? Have you tried some carbon components and switched back to aluminum? Or are you an ardent supporter of steel, with no carbon to be found anywhere in your garage?